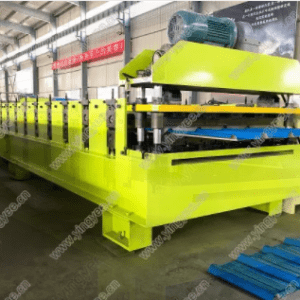

Hlau IBR ru tsev ntawv yob txoj kev tshuab

Lus piav qhia luv luv:

Wtxheej txheem orking:

Cheebtsam:

Phau ntawv - coiler x1 seb l

Kho tau nkag khoom siv x1 seb l

Main yob tsim tshuab nrog chromed phaj x 1set

Hydraulic txiav qhov system x1 seb l

Hydraulic chaw nres tsheb x1 seb l

PLC Tswj qhov system x1 seb l

Khiav-outtable x 1set

Technical parameters

| Phau ntawv decoiler | 1: Max dav ntawm raw khoom: 1300mm2: Peev: 5000kgs3: Inner diameter ntawm coil: 450-600mm |

| Roll forming tshuab | 1.Matching khoom: PPGI/GI/Aluminium 2.Material thickness: 0.2-1mm3.Power: 7.5kw4.Forming ceev: 0-30m/min5.Qhov dav ntawm daim hlau: raws li cov drawings6.input leveling khoom: adjustable li duab .7.Roll chaw nres tsheb: 228.Ncej Khoom thiab txoj kab uas hla: cov ntaub ntawv 45 # hlau ¢80 hli,9. Qhov siab: 10m±1.5 hli10.Txoj kev tsav: saw nrog lub cev muaj zog 11.Controling system: PLC 12.Voltage, Zaus, Theem: nyob ntawm tus neeg thov 13.Material of forming rollers: 45 # steel heat treatment and chromed 14Materialofcutterblade: Cr12mouldsteelwith quenched treatmentHRC58-62 15. Sab phaj: steel phaj nrog Chromed. |

| Txiav (Hydraulic Guide) | 1. Txiav cov lus tsa suab: Lub tshuab tseem ceeb tau nres thiab tom qab ntawd txiav.Tom qab txiav, lub tshuab tseem ceeb yuav pib.2.Material ntawm hniav: Cr12 pwm steel nrog quenchedtreatment58-62℃3.Length: Tsis siv neeg qhov ntev ntsuas 4.Kev siab ntev: 10+/- 1.5mm |

Duab

坐前面带出料.jpg)

坐前面带出料-300x225.jpg)

左前面带出料斜上-300x225.jpg)

左后面斜上-300x225.jpg)

右后面斜上-300x225.jpg)

成型产品效果-300x225.jpg)

切断部分电动切断-2-300x225.jpg)

前面带出料-300x225.jpg)

后面斜上-300x224.jpg)

坐前面带出料-300x225.jpg)

左前面带出料斜上-300x225.jpg)

后面斜上-300x224.jpg)

成型产品效果-300x225.jpg)

切断部分电动切断-2-300x225.jpg)

前面带出料-300x225.jpg)

右后面斜上-300x225.jpg)

左后面斜上-300x225.jpg)