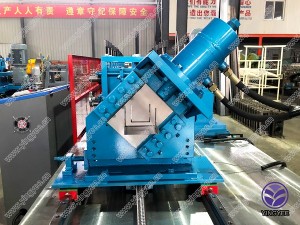

Lub tshuab no tuaj yeem kho qhov dav rau qhov sib txawv qhov sib txawv lub teeb keel, stud thiab taug qab, Drywall, C channel, U channel, phab ntsa kaum.

Lub tshuab yog tsav los ntawm tus kheej ua Iav Box uas muaj qhov tseeb dua thiab tsis muaj suab nrov.

Lub cev muaj zog muaj peev xwm txav tau cov phab ntsa vaj huam sib luag los kho qhov ntau thiab tsawg.

Main technical parameters

1.Hydraulicdecoiler

Muaj peev xwm: 3Tons Hydraulic

2.Tsis siv neeg hloov Feding qhia system

Input dav adjustable

3.Tsis siv neeg hloov loj Maily forming system

Lub zog loj: 7.5kw

Qauv: Coj Pillar

Ncej: Tag nrho cov hlau phaj rau tshuab lub cev

Kev sib sau ceev: tsis nres txiav, txhua qhov ceev yog 0-30m / min

Ncej khoom thiab txoj kab uas hla: # 45 steel thiab 60mm (Ua cov hlau rau cementation)

Cov khoom siv rau cov menyuam:: Cr12 nrog kev kho cua sov zoo, 58-62

Cov kauj ruam tsim: 12-14 kauj ruam rau kev tsim

Tsav: iav nrog channel

Lub cev muaj zog rau kev hloov pauv

4.Hydraulic Punching system (H qhov)

5.electronic part

Inverter: Delta (Taiwan)

Encoder: Nyiv Omron (Nyiv)

Servo lub cev muaj zog: shanghai Zoncn, 1.5kw

Tsawg-voltage apparatus CHNT (Tuam Tshoj)

Voltage: 380V 50Hz 3 theem

6.Logo punch LOGO

Logo xuas nrig ntaus ntawm kab tsis muaj qhov nrawm nrawm.

7.Cutting servo lub cev muaj zog tswj tsis nres

Hydraulic txiav system

Khoom siv: Gcr12

Txiav fais fab: 2.2kw

Raws li kev kos duab, xav tau hloov 10 txiav hniav rau 20 profiles.

8.PLC (zoncn) tswj thiab kov npo.PLC (zeeg)

9.Tsis siv neegReceiv rooj.

Post lub sij hawm: Dec-01-2020